In operating any electrical power system, engineers and operators must contend with the presence of harmonics.

Here, we’ll discuss what harmonics are, what effects they have on your power system, the electrical systems around you, and your company budget! We’ll also discuss how to find effective solutions to mitigate and deal with them.

What Are Harmonics?

Many who hear the word “harmonics” may think more along the lines of musical harmony or sound waves rather than electrical currents, but if so, you may be intrigued to know that you’re not that far off in terms of how it all works.

In electrical currents, harmonics describe the waveform pollution that comes from additional frequencies resident in your system’s current.

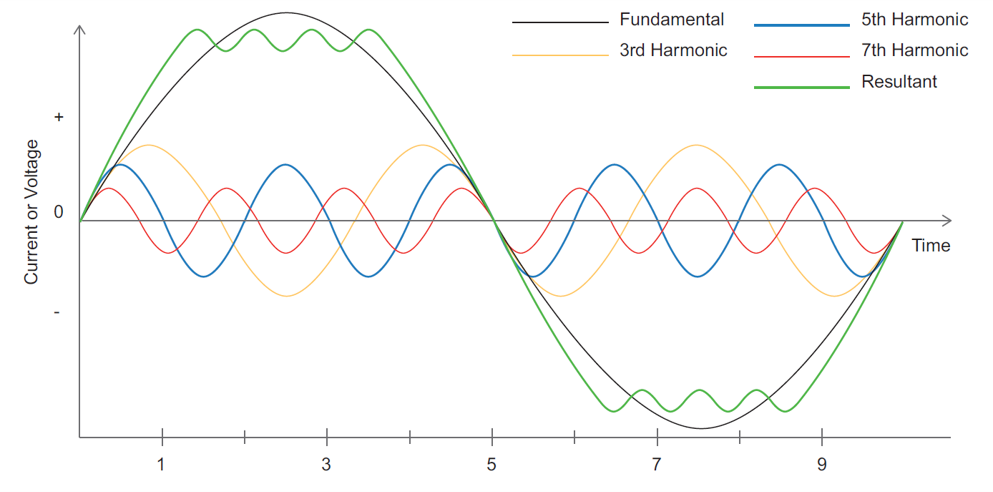

When viewed as part of a system analysis, harmonics comprise one or more sinusoidal waveforms (sine waves) that appear as additional frequencies that are top of the fundamental frequency, in your system’s electrical characteristics. They are almost always present in some capacity in the normal operation of electronic equipment.

These additional waveforms are integer multiples of the fundamental frequency of 60 Hz, which is the standard for most of North America, creating waves at 120 Hz, 180 Hz, 240 Hz, and so on. These extra frequencies appear as an undercurrent (or undercurrents) of the standard 60 Hz sine wave and are often called the third harmonic (120 Hz), the fifth harmonic (180 Hz), and so on.

Whether you have a single-phase or three-phase system, harmonic waveforms can and will appear in your system. These additional frequencies draw current in a non-sinusoidal manner, which in turn distorts the fundamental sinusoidal waveform, causing the resultant cumulative wave to have a more jagged and non-sinusoidal frequency.

To think of it in a simpler way, imagine it like sound. The fundamental 60 Hz frequency is the sound your system is listening for, and it can intake that sound for the best power quality.

However, while trying to listen for that sound, there are other forms of sound waves that can distort what your system is hearing. Like having a loud TV on or noisy neighbors (more on bad neighbors in a minute). It’s no wonder why harmonics is often referred to simply as “noise.”

The other noises your system hears can make it difficult to hear the fundamental sound clearly enough, and like a noisy atmosphere can distort what you hear in a conversation with your co-worker, noisy harmonic waves can distort your fundamental frequency.

This distortion in your electrical waveform is referred to as harmonic distortion or harmonic pollution. By pulling the current off its normal-flowing sine wave, this distortion causes degradations in power quality which can cause a myriad of other issues.

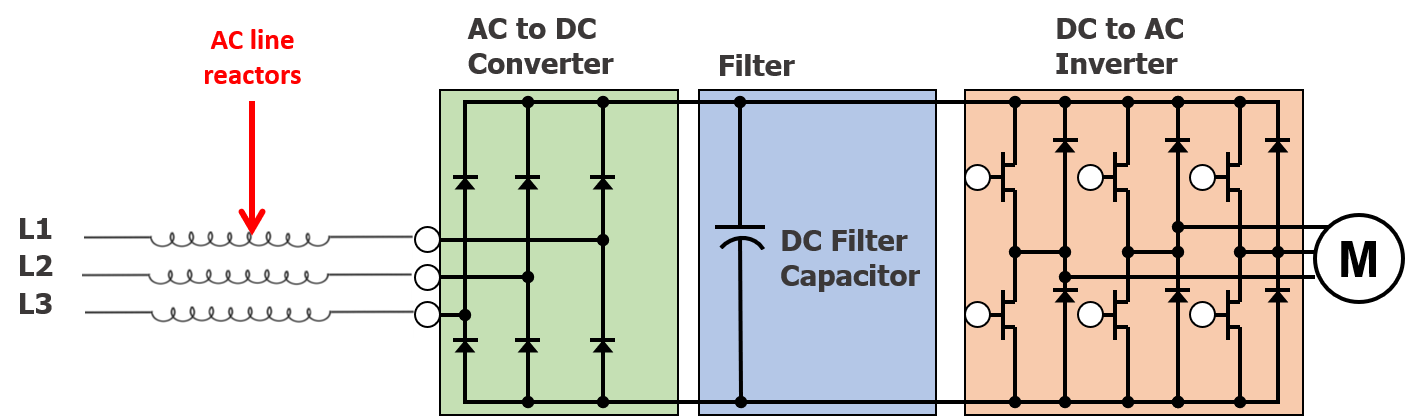

The sources of harmonic distortion in most power systems are non-linear loads which are devices that take AC power from the utility grid, convert it to DC power, and then use devices to make the DC into an artificial AC form again, to control loads like lights, computers, and other devices.

The most prominent non-liner loads are VFDs, or variable frequency drives. Often called inverters or variable speed drives, VFDs have multiple non-linear components, and the electromagnetic waves of those components create non-linear loads that disrupt the standard frequency of the system. Why are they the most prominent? Because they control electric motors and over 65% of the power used on our grid goes to motor loads. So, while VFDs are an important part of most power systems, their effect on electrical frequencies must be effectively managed.

What Do Harmonics Do to My Power System?

The effects of harmonics can be widespread, and they’re not pretty. Unmanaged harmonics are a detriment to your operation’s power quality, system health, operational efficiency, and even your company’s reputation and bottom line.

Sometimes it seems like a system has a ghost in it, interfering with control systems and even electronic communications, causing flickering lights and blown fuses. Even before more damaging effects might develop, the system may experience overheating, de-rating of power supplies, resonance frequencies which can damage rotating equipment, and even issues with simple tools like telephones and clock syncing.

You may eventually run into more serious problems with critical equipment, seeing things like motor bearing failures, motor insulation aging prematurely, conductors overheating, and destruction of capacitor banks. Standby generators can even become erratic in operation. In single-phase systems, harmonics can also create high neutral-to-ground voltages which can overload critical equipment.

Left unchecked, harmonics can lead to motor failures, which means downtime. Since harmonics run at higher frequencies than a standard waveform, motors can experience high core losses which will heat up the motor and shorten its lifespan. In particular, the fifth harmonic causes a counter electromotive force, or CEMF, acting in direct opposition to the motor’s rotation. While this harmonic wave isn’t substantial enough to completely counteract or reverse engine rotation, its effect does play a factor in decreased motor rotating speed and efficiency resulting in higher maintenance and production costs.

Devices that depend on and use communication interfaces, like VFDs and data processors, are the most prominent harmonic polluters. For systems using those tools, it’s important to remember that any electrical equipment in your facility can develop problems as a result, as referenced in IEEE 519-2022.

Why do Utility Companies Care About Harmonics?

Just like other forms of pollution, the effects of harmonics aren’t just confined within a given system. Distortion in power can go downstream and interfere with local electrical systems and neighboring company operations.

Because of this, the Institute of Electrical and Electronics Engineers (IEEE) introduced IEEE 519, a set of structured parameters for facilities to follow. This set of guidelines defines the appropriate level of harmonic pollution depending on the size and scope of a facility’s load requirements.

The ultimate purpose of IEEE 519 is to define how any given power system should work so that any given company can best be termed as a “good neighbor.” Mitigating the harmonics in a facility helps to decrease the detrimental effects that facility will have on systems outside of local operations. Failing to address harmonic issues can have a negative impact on how your company is perceived and create difficulty in maintaining positive relationships within communities.

Unfortunately, there are many companies who are either unconcerned with the harmonics that reside in their system or don’t see the problem as an issue to address because of the cost of putting countermeasures in place. As a result, utilities do have other ways of “helping” you get the point.

Utility companies often use the guidelines set in IEEE 519 to decide that a system has a problem and then take actions to force corrections. These can include actions as severe as fining, penalties on the power bill, or worse. This impact on the financial side of your business isn’t likely to go unnoticed, and unless addressed, could happen again and again.

If the problem continues, utilities may even exercise their right to cut off power to your facility. Many utility leaders such as Rocky Mountain Power, a division of Pacificorp, have built into their terms of service that failure to meet guidelines for harmonic distortion can result in termination of service.

At the extreme, if harmonics are found to be liable for damage to other systems, polluters can find themselves wrapped up in a lawsuit.

It cannot be overstated that the effect your system’s harmonics have on others will not go unnoticed or ignored. Don’t make the mistake of considering a major issue to be a minor one. Do your part to be a “good neighbor,” and make sure your power system isn’t causing issues for others.

How Do I Fix Harmonic Distortion?

Every engineer or electricity professional wants to see their system cause as little distortion as possible. The way to deal with the pollution that is harmonic distortion is through the process of harmonic mitigation. Harmonic mitigation refers to the methods professionals use to control harmonic pollution in power systems.

Because not all electrical systems are equal, harmonic mitigation doesn’t take just one form. There are a variety of component solutions that provide harmonic mitigation, some more common than others. The most important point is that a solution is applied, as the total harmonic distortion of a VFD by itself is usually around 100%.

Here are a few of the methods available to mitigate the harmonics in your system:

1. Line Reactors

Many companies already have reactors in their system, as this is often the first solution to consider.

A line reactor, also known as a choke or inductor, is an electromagnetic device that protects equipment from electrical disturbances and input power disruptions. It’s made up of a steel core wrapped with copper coils that create a magnetic field when current flows through them. This magnetic field helps to:

– stabilize electrical currents

– reduce harmonics and transients

– limit the rate of current rise

– protect electrical devices

– increase the impedance of the line

Line reactors are a recommended component for all VFD and motor systems to get a minimum level of harmonic correction for a lower cost. They are not singularly capable of mitigating all the harmonics in your system, but a typical AC line reactor offers roughly 3-5% impedance on the line and can lower harmonics created by a VFD to 35-40%, from the typical 100% distortion a drive delivers with no magnetic device.

2. Passive Harmonic Filters

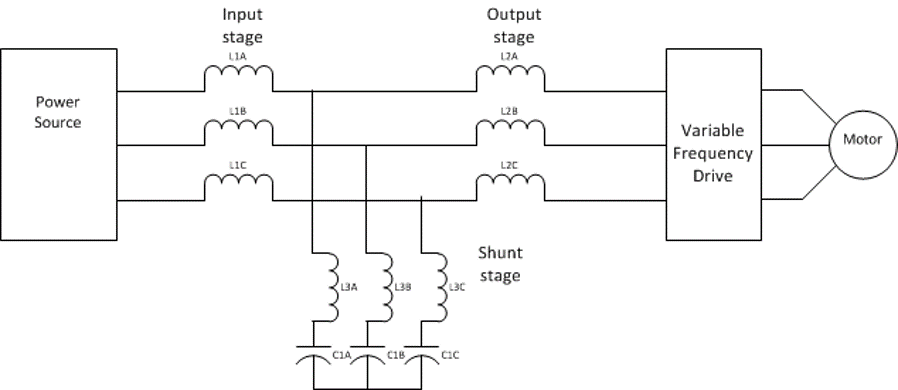

A passive harmonic filter is a more advanced mitigation tool designed to be applied to a specific current rating of a VFD. Passive filters create a tuned circuit that absorbs harmonic currents with a combination of capacitors, inductors, and resistors, “tuned” to address specific harmonics.

There are different types of passive filters available, depending on the needs of the system. High-pass filters allow all frequencies above a certain lower cut-off frequency. Selected frequencies below a specified cut-off point are then mitigated. Low-pass filters function similarly, except that they reduce all harmonics below the cut-off but do very little for high frequencies.

Passive filters are designed to be customizable to address specific applications and specific mitigation needs. They will commonly be able to reduce distortion to between 5-15% based on how they are configured. This is the most common solution to address and meet the levels of IEEE 519.

3. Multi-Pulse VFD Systems

Assuming, of course, that a VFD may be the primary source of harmonic distortion, another option available is to increase the number of pulses in a drive system. Base drives are produced as “6-pulse” without any method of harmonic mitigation involved. As we already stated, the harmonic distortion created can be equal to or greater than the fundamental frequency by 100% or more!

Another method to resolving the issue of harmonics is through an older, but trusted technology, called multi-pulse drives. This topology uses a combination of additional diode bridges, which are the switching mechanisms which create the waveforms, along with a phase-shifting transformer. This design literally increases the number of pulses that create the sine wave, typically to either (12) or (18) pulses, reducing the size of the “peaks and valleys” that are created with fewer switching devices.

These higher-pulse systems tend to be highly engineered, have very specific electrical system characteristics required to perform at peak efficiency, and are more costly. There are also more points of potential failure as there are more “moving parts” creating the mitigating technique.

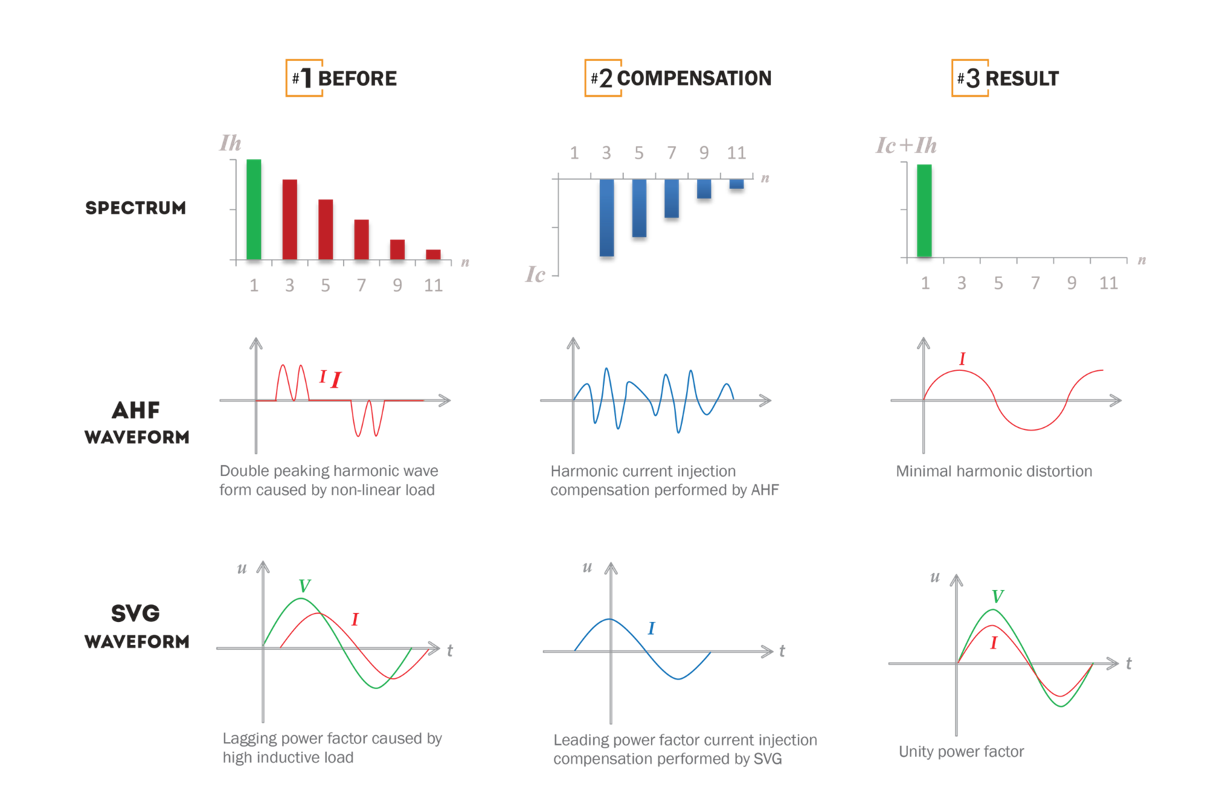

4. Active Harmonic Filters

Active harmonic filters, also called AHFs, are filters typically applied to multiplier drives on an electrical bus. AHFs use microprocessor-based technology to literally “read” the harmonics generated by the drives, and then create a counteracting waveform to create a nearly perfect sine wave. When it comes to pure effect, this solution is one of the most highly trusted in the industry.

AHFs work by utilizing a built-in digital signal processor (DSP) with a micro-second response time. This DSP analyzes the harmonics in the system and then uses its analysis to create a sine wave 180 degrees out of phase with the current harmonic waveforms. This response wave balances out the harmonics in the system, leaving one clear standard frequency and preventing corruption of power distribution systems. They will typically reduce harmonics to 5% or less and will also correct power factor issues that may exist on the same system.

Now, because an active filter is, virtually, a drive that creates pulses in the opposite direction of the base drive, they can be more costly than more common magnetics solutions. This is why an AHF is typically applied to multi-drive line ups to address harmonics created by several drives, with one solid state solution.

How Does PQC Help Battle Harmonic Distortion?

Power Quality Components works to help you improve your system. We are experts at addressing harmonic mitigation with industry leading solutions, and we also supply power factor correction and output filtering, among other things.

The world-class brands offered by PQC include Hans von Mangoldt Magnetics, Frako capacitors and capacitor contractors, and Galt Electric Active Harmonic Filters, as well as Static Var Generators for microprocessor-based power factor correction. Our team will work to recommend and supply the right equipment, ensuring the right solution for the right application.

For more information, contact our sales team at 1-800-595-5314, or email us at sales@pqcomponents.com.