When it comes to motor control, understanding the distinction between the line side and the load side is crucial for maintaining power quality and ensuring the efficient operation of your systems. This knowledge helps in selecting the right components and addressing potential issues effectively.

For this article, we’ll define the midpoint of your power system that determines the difference between line and load as the device controlling your motor, such as a variable frequency drive (VFD) or a reduced voltage soft starter (RVSS). With that in mind, when considering which side of your system to address, the question becomes, “Is the power coming to my VFD or going from it?”

The Line Side (Incoming)

The line side refers to the part of the electrical system that connects the power source to the VFD. This side handles the incoming power, and attention must be given to the power’s quality, ensuring that the motor receives the right voltage and frequency.

The line side of a VFD includes more than just the power line. It can also include the breaker, the transformer, and anything else that is “upstream” from your drive helping to regulate incoming power. The reason operators need to pay attention to the line is because the VFD itself could experience, or even cause, issues with power quality on this side, such as harmonic distortion.

The Load Side (Outgoing)

The load side refers to the connection the VFD has to the motor itself. On this side, an operator is responsible for managing the power delivered to the motor, ensuring smooth operation and longevity.

Managing the load side is important because you’ll take charge in ensuring your motor doesn’t fall victim to damaging side effects like dV/dt, voltage spikes, or reflective wave phenomena. These factors directly affect the performance and lifespan of your motor and have a significant impact on how well everything runs in your operation.

Components to Consider

When looking to improve your system, there are many different components that can help resolve different issues you may run into. Some components are built purely to resolve an issue on either the line or load side alone. Many, however, are more versatile depending on how you apply them, and they can contribute to resolving, if not fully resolve, matters on both sides.

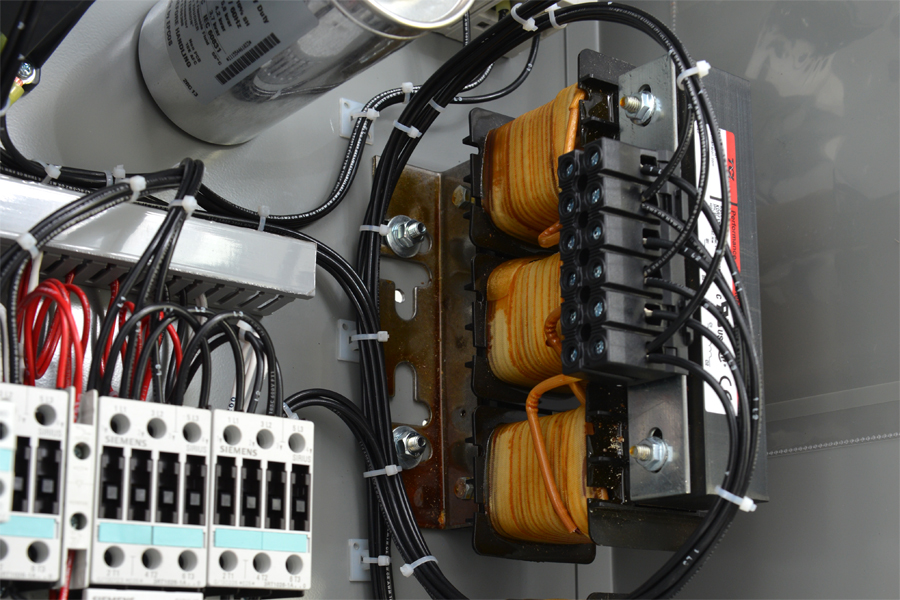

1. Reactors

Reactors are inductors consisting of copper wire or aluminum plating wound around a steel core to create a magnetic field. A reactor is applicable to both sides of your power system depending on its setup, each application accomplishing different outcomes. Because of this, the industry is often familiar with the terms “line reactor” and “load reactor.” What makes a reactor specifically one or the other is how it’s applied to your system.

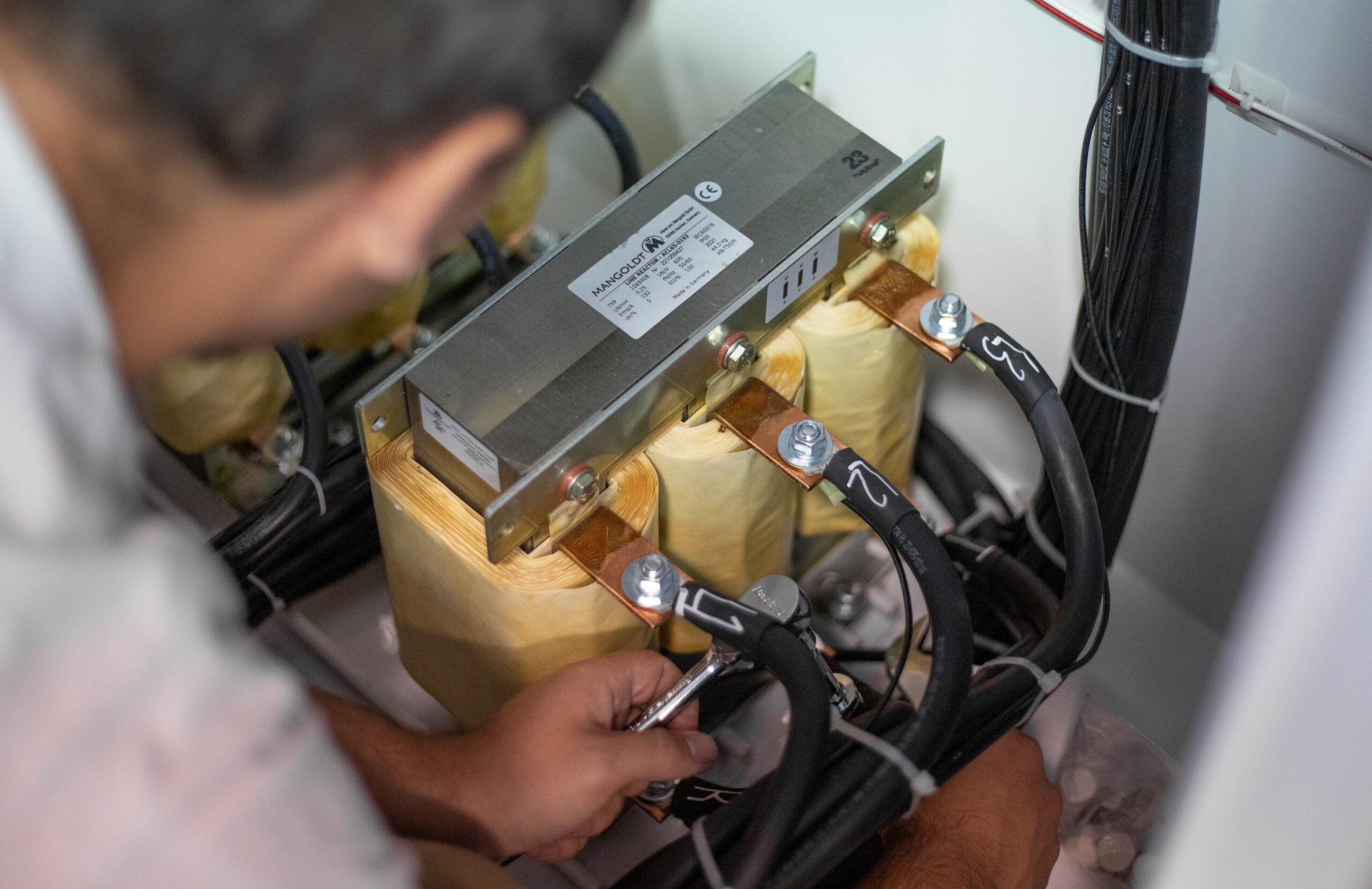

Sometimes a manufacturer will say that a particular reactor is only rated for line side or load side use. While there’s not anything technical typically holding it back from being used on both sides, you may be going against manufacturer recommendations and voiding warranties through incorrect use. Brands like Mangoldt rate their reactors for both sides of the system, making it a lot more straightforward in application.

A line reactor, also called an input reactor, is installed between the power system and the controller or VFD. This serves the purpose of reducing the effects of harmonic distortion. The reactor helps to stabilize the electrical current traveling through the controller so that there isn’t a heavy presence of additional frequencies backflowing into the system. You’ll also have moderate surge protection from it, but it’s not recommended to rely on a reactor as a surge protection device (SPD).

A load reactor, also called an output reactor or an output filter reactor, is placed between the VFD and the motor. We recommend looking at adding a load reactor on any lead over 100 feet long. This reactor serves to regulate the voltage frequencies traveling to the motor, mitigating voltage spikes caused by dV/dt by providing between impedance on the load commonly around 3-5%. That said, when using a load reactor, a motor with a lead length over 1,000 feet likely won’t see its dV/dt issues resolved by a reactor alone and will need a more advanced solution like a sine wave filter.

2. Capacitors

Capacitors work to store electrical energy in a temporary circuit. They do this for the purpose of tempering the power input and output (depending on application), thus taking somewhat of a broad–stroke approach to power quality improvement. Like reactors, their application can work on both ends of the controller.

It’s important to note that although capacitors can be sold or used independently, they often are a critical part of a larger compound solution, such as a passive harmonic filter or a sine wave filter. In these systems, a capacitor operates to store energy that moves through the whole system, providing more in-depth resolutions to power quality issues.

3. Filters

“Filters” is a broad term when it comes to AC motor systems because there are multiple factors in your operation that could require filtration. Many of the filtering solutions offered by Power Quality Components are designed to offer heavier harmonic or output filtering than what you’d get from a reactor.

A harmonic filter is used to mitigate distortion on the line side caused by the backflow of harmonic frequencies into the power system. While a reactor is less expensive, it often can’t bring a VFD into compliance with harmonic regulations from your utility provider. A passive harmonic filter combines an array of reactors and capacitors to counteract the additional frequencies tailored to specific current, while an active harmonic filter (AHF) is designed to be able to read frequencies in real time and create a near-perfect counteracting waveform against the harmonics.

On the load side, you may employ a dV/dt filter or a sine wave filter. From testing results, a load reactor offers similar performance to a dV/dt filter, although dV/dt filters are typically more expensive. A sine wave filter is more attuned to mitigating voltage spikes in motor applications with longer leads from the VFD and provides a better output waveform

Improving Line and Load Efficiency with PQC

Understanding the difference between the line side and the load side in motor systems is fundamental for maintaining power quality and ensuring efficient operation. By knowing the specific components and their roles on each side, you can better manage your system, troubleshoot issues more effectively, and ensure the longevity of your motors.

At Power Quality Components, we specialize in improving efficiency on both sides of VFD applications with the expert engineering of brands like Frako, Mangoldt, and Galt. Our team of consultants and subject matter experts will work with you to tailor a customized solution for your system to deliver the most efficient outcome possible for the right price.

To speak with a representative today and get started, contact us at 1-800-595-5314 or email us at sales@pqcomponents.com.