Chances are your power system isn’t getting everything it can in terms of efficiency. The percentage of the power that your system is using versus the amount of power the utility supplies is what’s referred to as the power factor. Understanding power factor is a critical part of building and maintaining an energy-efficient system.

Understanding power factor is a critical part of building and maintaining an energy-efficient system.

What is Power Factor?

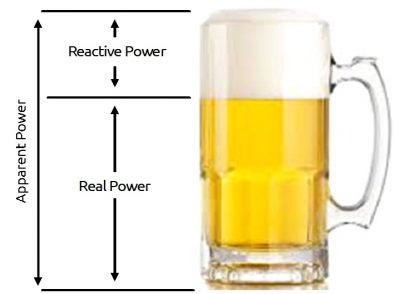

Power factor is how much of the power you pay for is actually doing work. It’s determined with a calculation that expresses the energy efficiency of your system by showing you how much of what it needs is being used. It is a ratio of working power (the power your system is using) to apparent power. Apparent power is also known as demand.

Working power, sometimes called active power, is measured in kilowatts (kW). This is the energy in your system that’s actually getting work done. If we were talking about the fuel in your car, working power would be the gas your car is using to turn the wheels and operate the engine.

A good way of visualizing working power is by comparing it to pouring a glass of beer. Working power represents the beer itself, but it’s not the only factor you’ll need to consider. Also in the glass is the foam that pouring your beer has produced.

The last part of the equation then is apparent power, which is the combined amount of both active and reactive power. It’s the glass holding your drink, both the beer and the foam. The larger a glass you need, the more you have to pay your utility provider.

Electrical energy efficiency is all about getting your system’s power as close as possible to unity power factor, which is your system using 100% of its power demand.

While you probably don’t want a flat beer after work, it’s what you should be aiming for when you’re on the job.

Image obtained from Tandem Energy.

Just like how pouring a beer produces foam, as your system consumes working (active) power, it also generates reactive power, which can rightly be referred to as wasted or lost power. This is power being generated but not used by your system.

Reactive power may not be helping your operation, but it’s still running up the bill with your utility. Reactive power is measured in kilovolt amperes (kVA).

How to Calculate Power Factor

The formula for calculating a circuit’s power factor is an easy one. Power factor represents the calculation of working power divided by apparent power, or

PF=kW/kVA.

The result of the equation is the percentage of how much of your circuit’s apparent power is used as active power. Ideal power factor is expressed as 1.00, or unity, while anything less efficient is typically expressed in a decimal format like .95 or .75. It can also be expressed as degrees, such as 95 or 75 degrees lagging, indicating how far the apparent power lags behind the normal sine wave (or ahead of it in case of leading power factor).

If you want a great online resource for power factor calculation, check out this calculator.

What Happens if Power Factor is Poor?

It’s important to know what your utility considers to be suitable power factor. Utility providers take interest in your system being efficient with the energy they provide for you.

Most utility companies mandate a power factor standard between .90-95. The more efficient the world gets, the higher the standard will likely be in the future.

For example, Rocky Mountain Power (RMP), a division of Pacificorp in the western U.S., sets its standard for minimum power factor at .90 lagging. Lagging indicates that the apparent power lags the working power. RMP puts surcharges on power systems with less than .90 power factor by increasing your meter’s power by ¾ of 1% for each .1 below .90.

Let’s say that your power factor is .75 lagging. Based on on-peak power charges by RMP, your utility charges you $13.92 per kilowatt for service of facilities over 1,000 kW and 11.74 per kW for services under 1,000 kW.

In that situation, the inefficiency of your system causes your utility to run you roughly an extra $1.32 (<1,000 kW) or $1.57 (>1,000 kW) per kW per month, but what would that mean to your operation? It may seem like pocket change until you consider how much power you’re probably using. Here are some averages for power usage for some of the most prominent industries we work with:

- Hospitals: ~5,000 kW

- School Districts: ~2400 kW (for 12 schools)

- Water Treatment Plants: ~355 kW

The charges can really add up based on the size and scope of your operation and its power needs. School districts could have over $3,700 in upcharges on their utility bills every month, and the average hospital could be looking at over $7,800 per month.

And that’s just the surcharges that go on top of an already ballooning bill based on your system requiring more demand than necessary.

Beyond just the dollars and cents, inefficient power factor can jack up the amperages in conductors and transformers, cause power shortages, and create the burden of needing larger conductors and other equipment.

How to Correct Power Factor

Power factor correction, or PFC, is the practice of modifying reactive current to reduce the amount of apparent power your system demands.

How you choose to correct poor power factor in your system is up to you, but the most important thing is to be proactive in tackling the issue.

Capacitors

When capacitors are added in parallel with connected circuits, they can act as generators of reactive power. This means that instead of your system generating that reactive power and driving up energy costs, it can draw from the capacitor instead. This makes it so that your motors, or whatever other equipment your system entails, can receive the same level of current without incurring higher costs.

Capacitors can be a quick and easy fix for power factor issues, but they are often the cheapest solution for a reason. The use of capacitors can cause leading power factor, which is when power factor goes over unity. If not calculated correctly, leading power factor can create issues with standby generators.

If relying on capacitors as a PFC solution, consider employing capacitor switching, which energizes and de-energizes different capacitor banks alternatively to maintain safe voltage levels.

Static Var Generator

A static var generator, or SVG, is another way to tackle the problem of reactive power. It works to either self-create or absorb reactive power based on whether it’s handling an inductive load (lagging PF) or a capacitive load (leading PF).

SVG’s are dynamic, so they can interpret and adjust to the demands of your power system. They’re like noise-cancelling headphones, where they monitor the conditions and actively adjust to counteract issues. This makes them less reliant on supervision and direct handling to resolve load conditions.

Using an SVG means you also avoid the hassle and potential voltage issues that you would have had with capacitor banks.

Active Front End Variable Frequency Drive (AFE VFD)

While not the most common way to handle power factor correction, it’s hard to argue with the results seen in the use of an Active Front End (AFE) VFD. Power systems utilizing an AFE typically see near-unity or perfect unity in their power factor ratings thanks to its dynamic adjustability and advanced technological edge.

AFEs, also called active rectifiers or active converters, convert AC power to DC power using strategies for active control. Rather than relying on traditional rectifier methods, AFEs employ Insulated Gate Bipolar Transistors, or IGBTs, to precisely control the flow of reactive power and smoothly regulate power factor at a near-unity level.

AFE’s use advanced algorithms to control the IGBTs’ switching, keeping the voltage and current constantly in phase. They can give you unity power factor for the system they are installed on, and often can use excess capacity to correct power factor elsewhere in your system.

Not every situation makes sense to install an AFE, but it can be a smart solution for when you’re already looking at installing a VFD in your system, or if you’re going to need an AFE to handle regenerative power on a VFD system.

Improving Power Factor with PQC

Power Quality Components takes pride in being experts at improving energy efficiency by providing plentiful and diverse effective solutions for power factor correction, harmonic control, output filtering, and more.

Our team operates throughout the United States, as well as with experience in international power systems. The team consists of engineers, experts, technicians, and leaders in the power quality industry who have been addressing power issues like harmonics, power factor, and dV/dt for decades.

To work with a member of our team for solutions with your power system, contact us at 800-595-5314 or ssales@pqcomponents.com.